Product Features

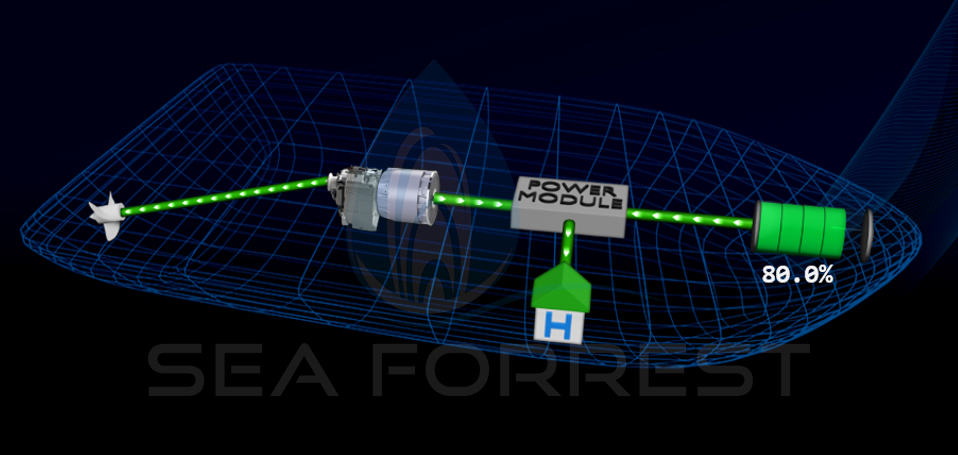

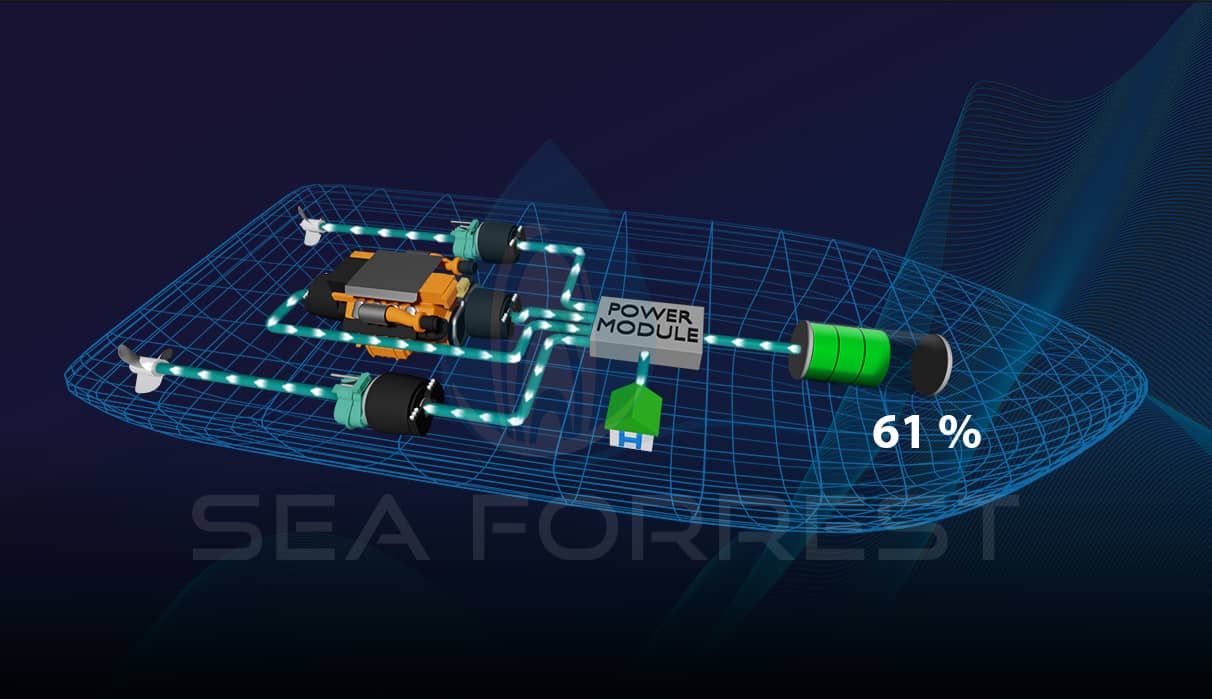

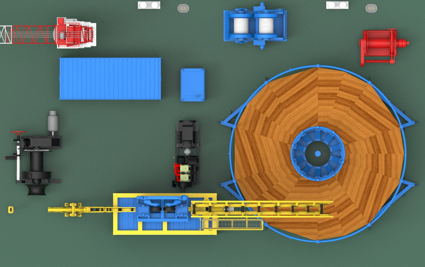

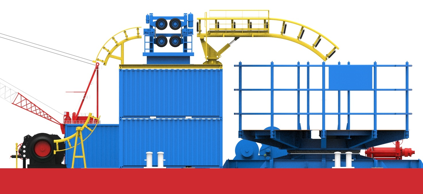

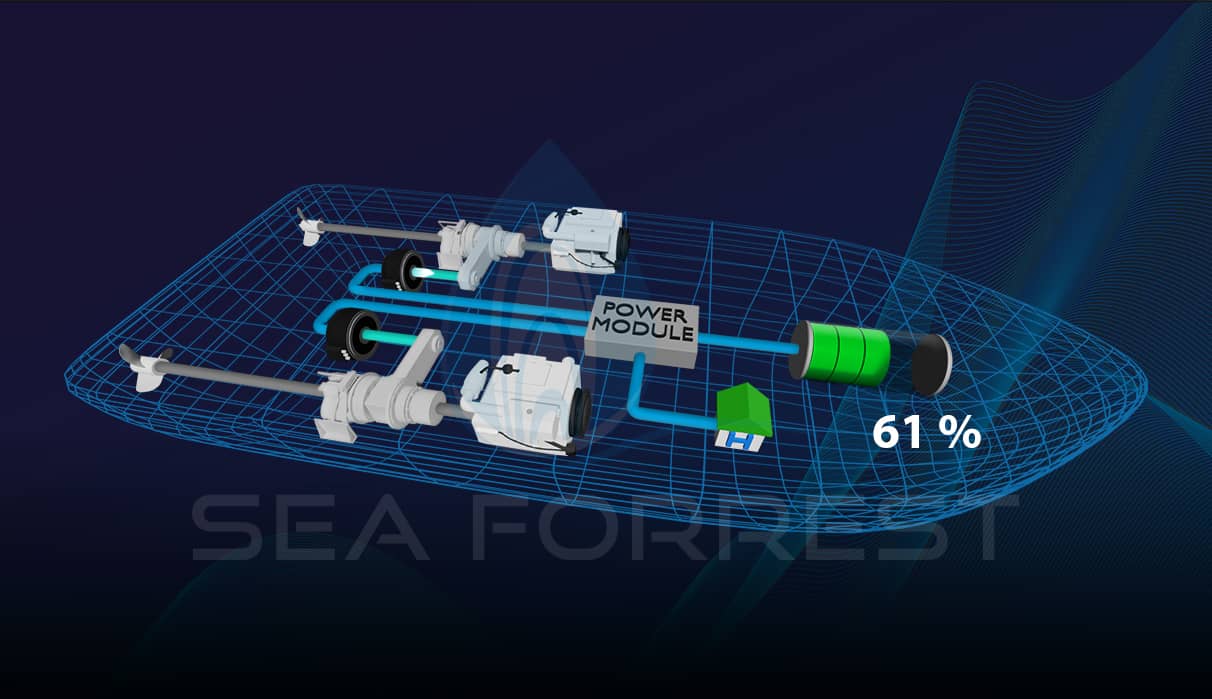

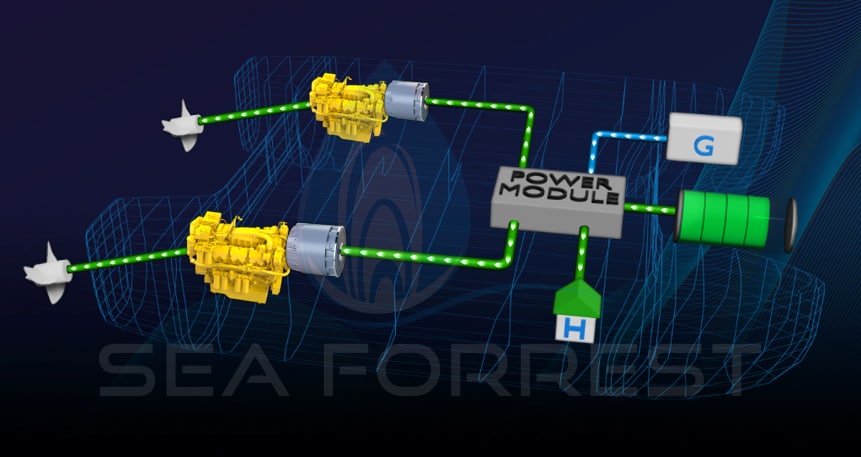

The Full Electric Propulsion System is engineered for zero-emission performance, operating solely on electric power. It utilizes onboard lithium-ion batteries to drive both the vessel’s propulsion and onboard systems, relying on both onshore and offshore charging capabilities. Designed for versatility, this system can be retrofitted to existing vessels or integrated into new builds, making it suitable for a range of applications, including harbor tugs, passenger ferries, supply boats, and harbor launches.

Electrical motor driven, zero emission

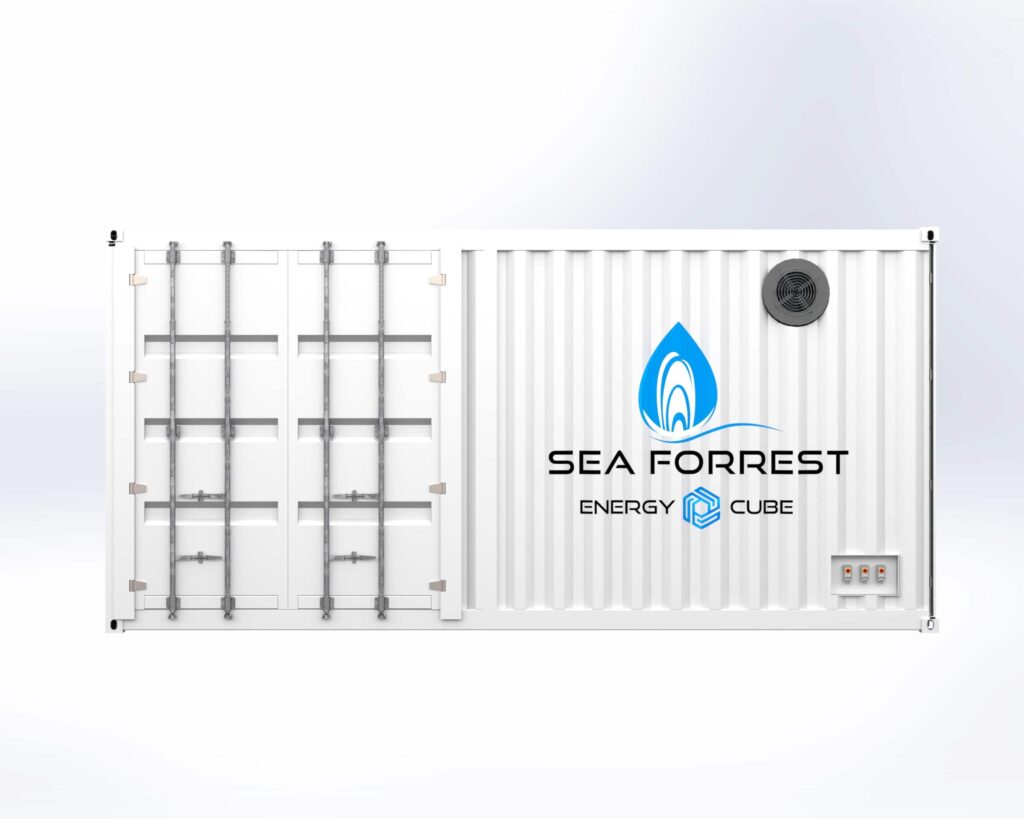

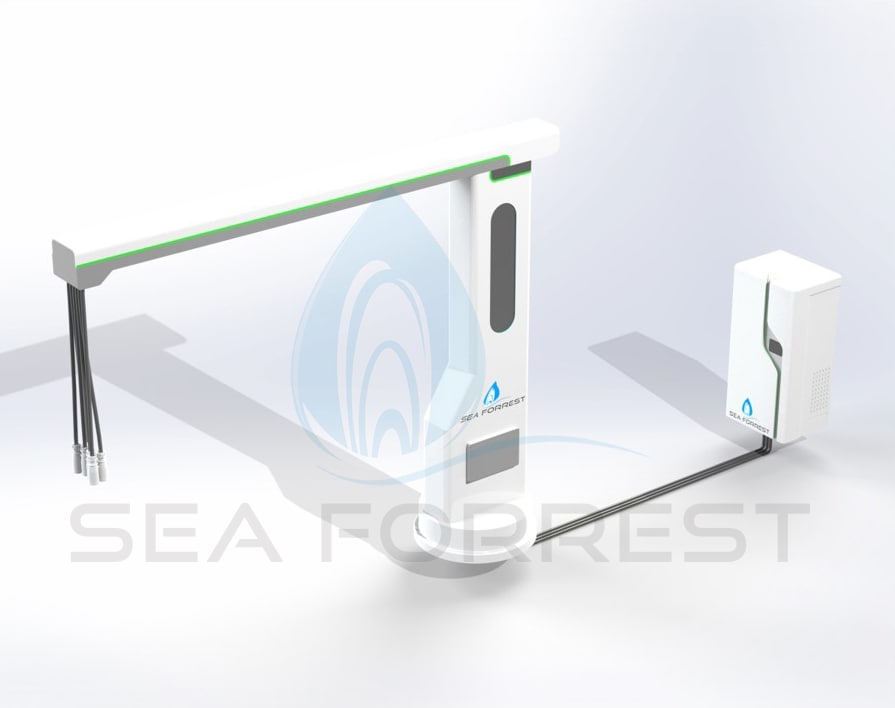

Power source - onboard lithium-ion battery and plug-in charging from shore

Charging infrastructure (shore & offshore) required.

Retrofittable to existing vessels or new-builds

Application: Harbour tugs, passenger ferries, supply boats, harbour launches, etc.